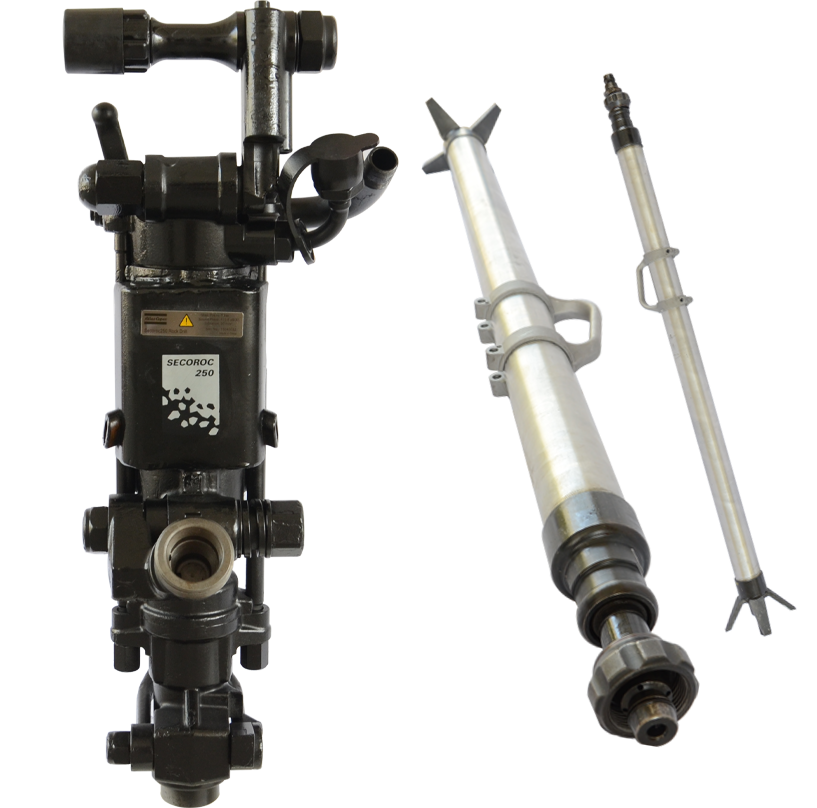

S250 Air Leg Rock Drill

During highway expansion, controlled blasting is required to shape cut slopes along mountains. The S250 rock drill provides stable vertical and inclined hole drilling, ensuring clean fracture planes and preventing excessive collapse.

This improves slope appearance, reduces rockfall risk, and ensures long-term road safety.

SPECIFICATIONS for S250 pneumatic rock drilling machine with air leg

|

Air consumption

|

3.7m³/5.0 bar

|

|

Air Connection

|

25 mm

|

|

Water Connection

|

12 mm

|

|

Piston diameter

|

79.4 mm

|

|

Piston stroke

|

73.25 mm

|

|

Blows

|

2050@5.0 /Min Bar

|

|

Total length

|

710 mm

|

|

N.W.

|

35Kg

|

Detailed introduction

S250 Air Leg Rock Drill

S250 Rock Drill is used for rock drilling, blasting holes and other drilling works in the quarries, small coal mines and other constructions.

S250 Air Leg Rock Drill

It is suitable for drilling and blasting under various of rocks at any direction angles.This machine could match with short air leg or long air leg.

Smooth and controlled drilling for safe rock face shaping

Based on the test results, S250 demonstrates the design results of precise mining. The on-site engineer reported a significant reduction in overexcavation and unstable rock profiles, which is difficult to achieve with traditional drilling rigs. The advantage of the S250 air leg rock drill lies in its patented stabilization system. The S250 air leg rock drill is different from old models that may not drill accurately in fractured geology. The S250 maintains excellent drilling straightness and alignment, making it an excellent helper for operators in drilling work. The accuracy of this drilling is quite important in rock drilling work, which affects the mining efficiency and drilling budget of the enterprise; When blasting rock in a mine, the energy generated by the blasting propagates along the predetermined direction and route of drilling, ensuring the smooth progress of rock drilling operations. The significant advantage it brings is a smooth and predictable rock surface that conforms to the direction of engineering design, minimizing the need for additional labor and the possibility of danger.

In addition, the S250 air leg rock drill is designed for harsh drilling environments in mountainous terrain. Its meticulous design can support the quick assembly of S250 on narrow workbenches, while its heavy components can withstand continuous vibration and abrasive dust. The S250 air leg rock drill is an excellent rock drill that can be used in variFor construction site managers, this means more reliable rock drilling speed, lower maintenance costs, and a safer workplace. The S250 air leg rock drill has provided excellent rock drilling performance from the beginning, not only accelerating construction progress, but also significantly reducing long-term costs related to slope repair and rockfall mitigation. The S250 air leg rock drill is an indispensable resource in mining exploration operations. From soft shale to hard granite, ensure optimal performance under various conditions and extend the service life of drill bits.ous environments.

DETAIL VIEW

Post time: Nov-11-2025